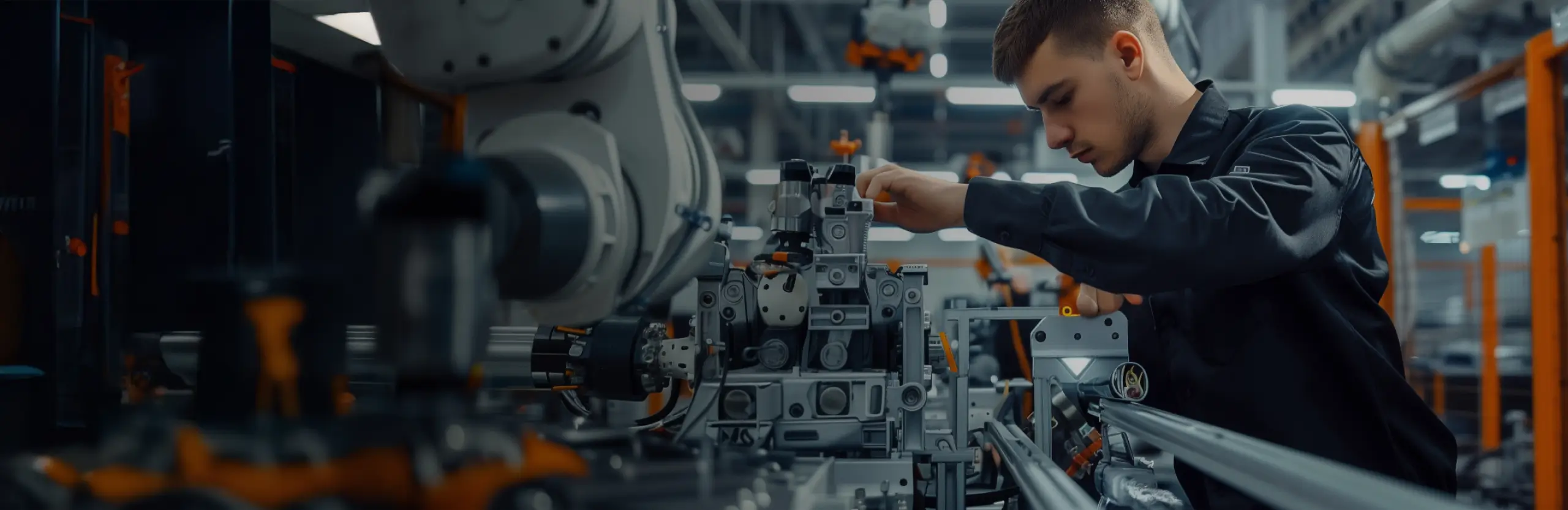

IoT in Manufacturing

IoT Manufacturing

Optimising

production

processes

Plant and

machinery

management

Quality

assurance

Use Cases

For specific industries

Remote monitoring?

IoT-connected devices with sensors let you monitor equipment usage and condition to assess their performance and service them in case of any problems.

Predictive maintenance

IoT solutions can gather data on tooling performance and health, helping maintenance teams better understand when to service production equipment.

Real-time production visibility

Thanks to connecting machinery to IoT-enabled monitoring platforms, plant managers can easily view all their machines and assess their performance against production goals in real time.

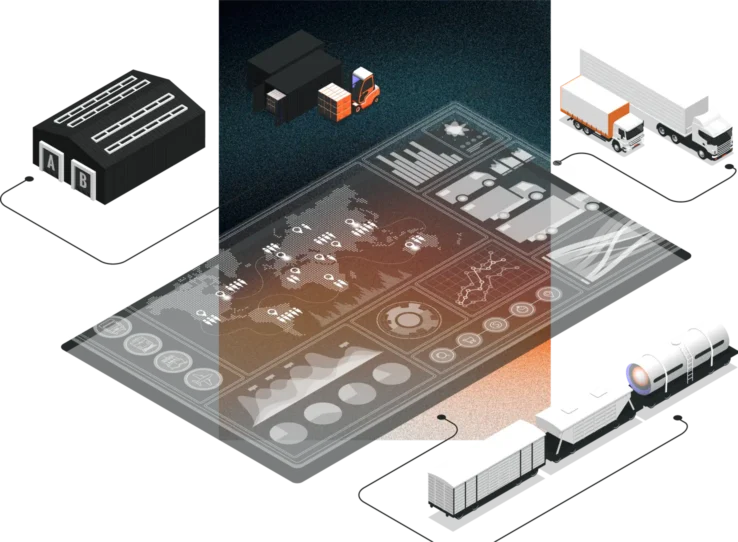

Supply chain optimisation?

IoT enables easier access and analysis of data on supply chain operations. As a result, production companies can better track assets, control inventory, and automate tasks.

Knowledge

Everythings is here

CAN Bus Data in Telematics:

a Practical Introduction

Telematics is taking modern logistics and fleet management by storm, and it’s easy to see why. 96% of companies using telematics surveyed by Teletrac Navman reported measurable savings, and almost half integrated AI-driven automation tools into their fleets. At the heart of this transformation is the Controller Area Network (CAN) Bus, the backbone of vehicle […]

What Agile Software Development Methodology Can Do For Your Next IT Project

Software project success rates are alarmingly low in today’s rapidly changing business landscape. According to Zipdo’s report from 2023, 31% of software projects are cancelled before completion, while over half of them almost double their initial budget. Perhaps the most concerning fact is that only 16% of IT projects are completed on time and within […]

LET’S TALK

For specific industries

FAQ: IoT in manufacturing: solutions for your company

Frequently asked questions

The use of IoT—the Internet of Things—in manufacturing involves connected devices, sensors, and systems that collect, analyse, and let companies extract insights from real-time production data.

This ability translates into multiple benefits, such as optimised process efficiency, machine and equipment usage, and reduced downtime, which all positively affect producers’ bottom lines.